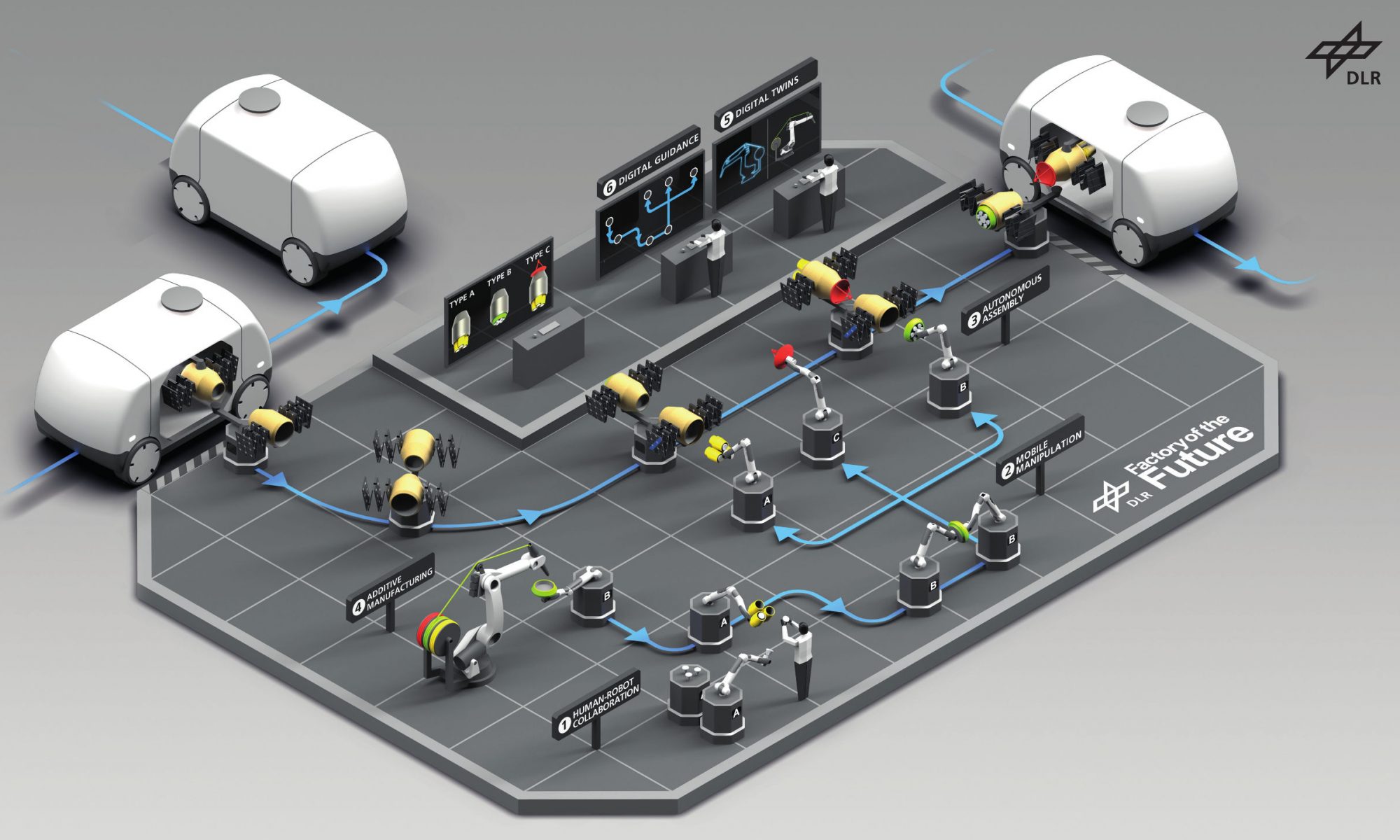

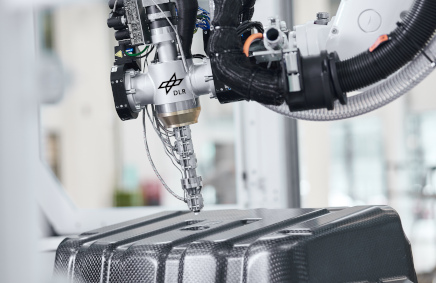

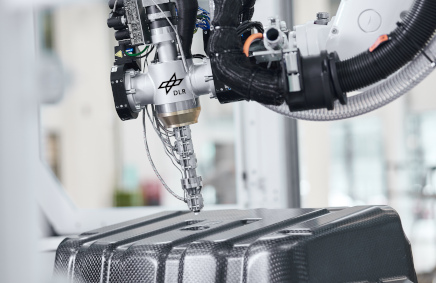

Das Ziel ist die digitale Transformation robotergestützter Produktionsprozesse im Rahmen der Industrie 4.0. Die Initiative des DLR verfolgt mit dem Projekt eine umfassende Strategie, indem sie Zukunftstechnologien und Ansätze aus der Forschung zu künstlicher Intelligenz und kooperativen Robotern untersucht – von neuartigen Ideen bis hin zu ausgereiften Konzepten. So wird Factory of the Future zum Vorreiter: Die Anwendung hochaktueller Forschungsmethoden aus Luft und Raumfahrt macht es möglich, Produktionsabläufe zu vereinfachen und zu optimieren.

Unsere Konzepte & Technologien

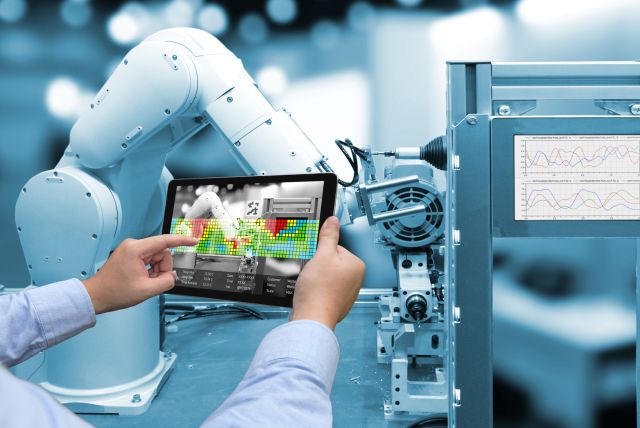

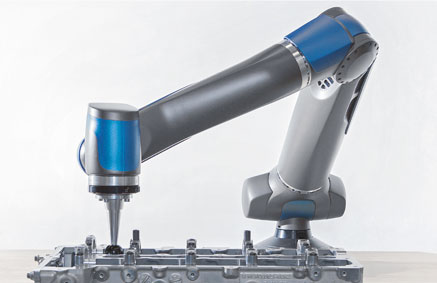

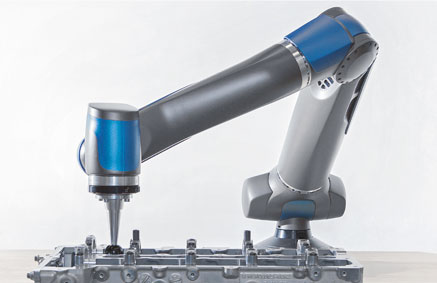

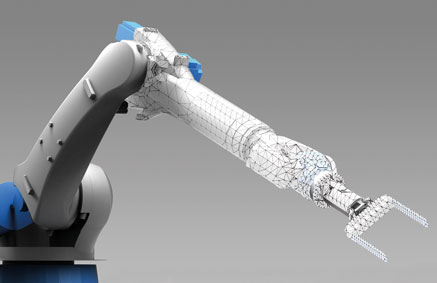

Unsere verschiedenen Robotersysteme und Anwendungen machen es möglich, den Anforderungen der Produktion der Zukunft mit klaren Konzepten und Lösungsansätzen zu begegnen: Individualisierte Massenfertigung, die Produktion kleiner Losgrößen, kurze Planungs- und Einarbeitungszeiten, intuitive Programmierung und sichere Mensch-Roboter-Kollaboration sind nur einige Bereiche, an denen wir verteilt über neun DLR-Institute arbeiten.

Lernen Sie die Factory of the Future besser kennen: Wir laden Sie ein, unser Forschungsprojekt und uns auf einer unserer Veranstaltungen kennenzulernen. Alle Neuigkeiten aus dem Projekt finden Sie hier.

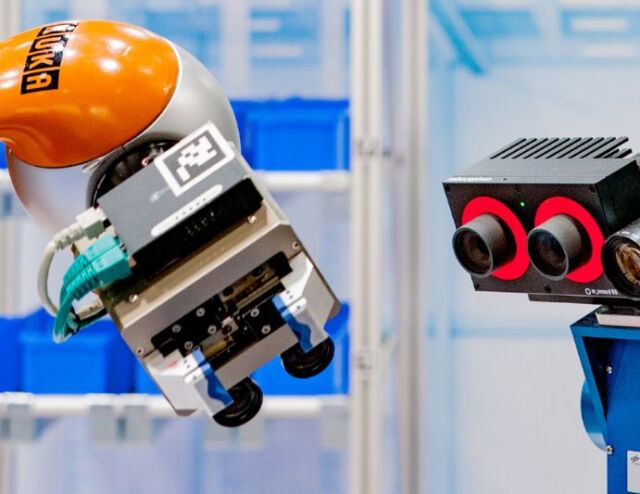

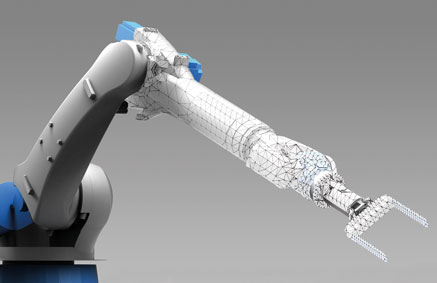

Flexibilität als wichtige Eigenschaft zukünftiger Robotersysteme

Save the date: Vom 9. bis 10. Dezember 2020 findet das 52. International Symposium on Robotics online statt

Das internationale KI-Projekt VeriDream wurde vom europäischen Innovationsrat mit 2 millionen Euro prämiert

DLR-Forscher entwickeln Algorithmus zur Übertragung von Wissen eines Roboters auf neue Produkte.

Save the date: Von 16. bis 19. Dezember 2020 findet die automatica in München statt

Workshop Factory of the Future – How to digitalize the robot-aided manufacturing process in Industry 4.0?

… am DLR-Standort Oberpfaffenhofen an diesem Sonntag, 21. Juli 2019, von 10-17 Uhr.

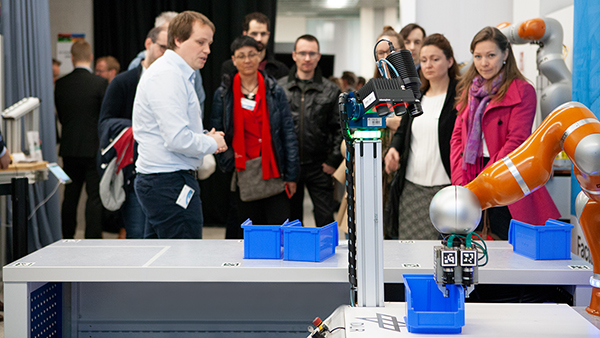

In Zusammenarbeit mit der IHK München & Oberbayern fand am 9. April 2019 die Veranstaltung „Forschung zum Frühstück“ am Institut für Robotik und Mechatronik des DLR statt.

Im April 2019 erschien ein Artikel zu Factory of the Future im A&D Magazin.

Im Dezember 2018 erschien ein Beitrag zu Roboterarm SARA auf der Website des A&D Magazins.

Vom 10. bis 13. November 2018 präsentierte die Factory of the Future ihre Demonstratoren auf den Münchner Wissenschaftstagen 2018.

Manchmal ist der direkte Kontakt der einfachste Weg. Gerne beantworten wir Ihre Fragen oder nehmen Ihre Anregungen entgegen!